Our commitment to cutting our aluminium recycling carbon footprint

As aluminium recycling specialists, our work is focused around giving the mountains of metal that passes through our gates a longer lifespan.

From cutting, grading and sorting metals for global smelters, to filtering and cleaning recyclable metal and aluminium can scrap so that it can be recycled back to its original form, we’re a key cog in the overall metal recycling journey.

Working to the highest environmental standards, our commitment to reducing our carbon footprint is underpinned by our ISO 14001: 2015 Environmental Management System accreditation, as well as our dedicated Environmental Policy.

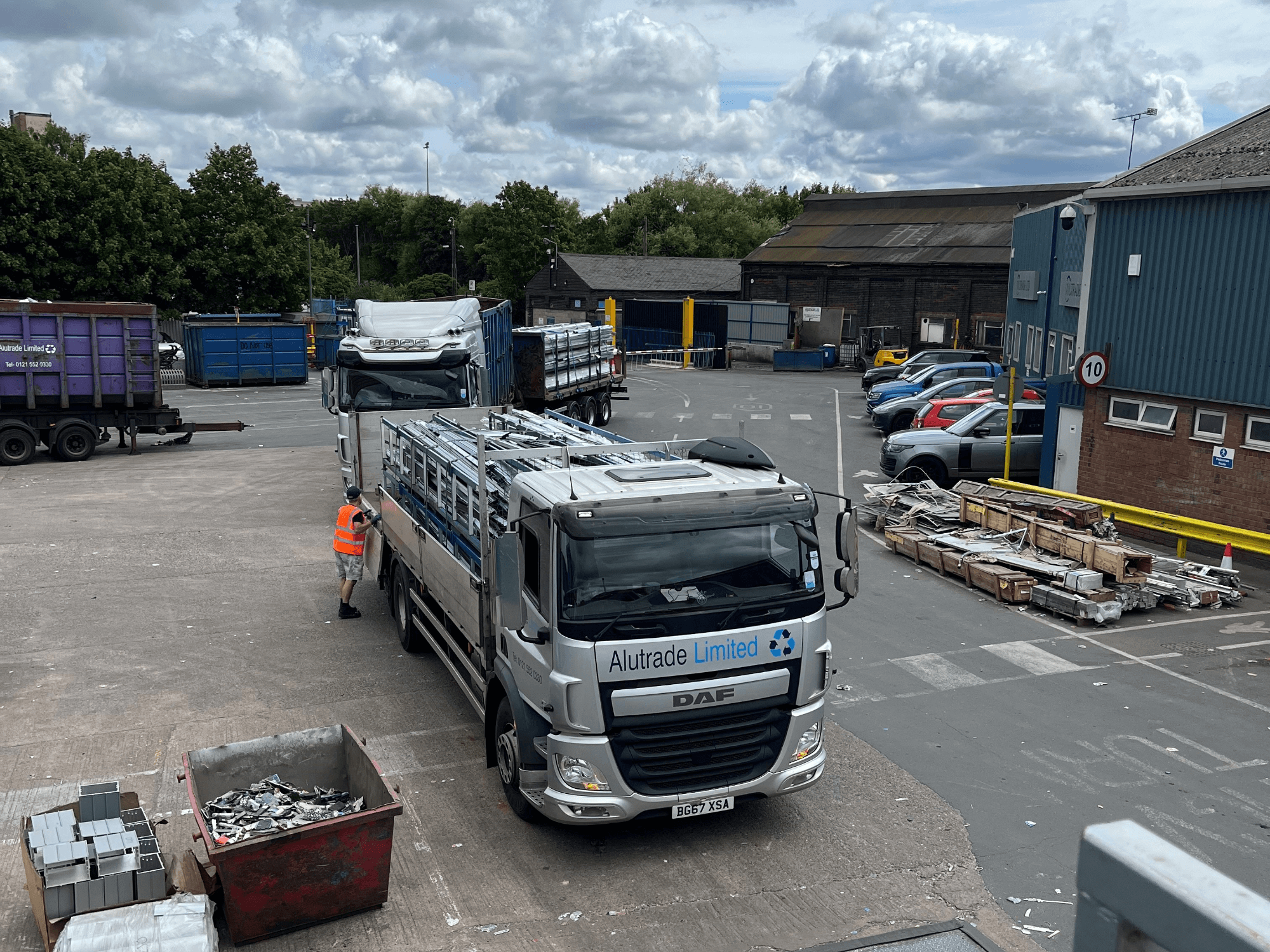

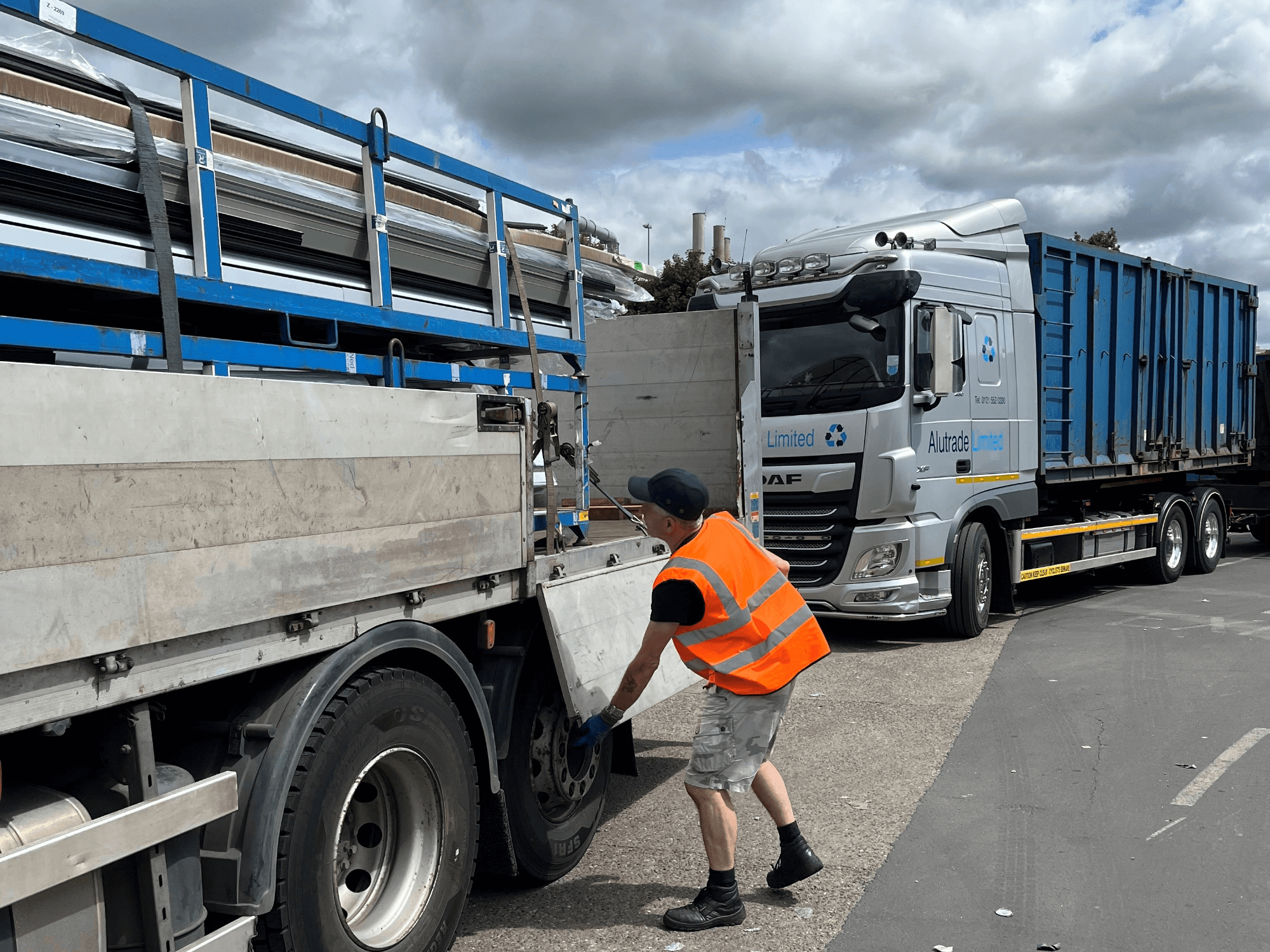

In addition to our on-site work, many of our team members and all of our aluminium recycling vehicles spend every day off-site, collecting and delivering metal across the UK. We currently make more than 6,000 annual collections, with our fleet of 12 lorries clocking up in the region of 41,000 miles, per vehicle, every year.

Being out and about on the roads is fundamental to our operations however, it doesn’t mean that our aluminium recycling collections and deliveries can’t be as environmentally-friendly as possible.

We’re continuously making improvements within this area, which includes:

- Educating all of our drivers on how to implement SAFED (Safe and Fuel Efficient) driving – backed by the Department of Transport, the SAFED training programme teaches LGV drivers how to adopt driving techniques that use up to 15% less fuel and emit fewer air pollutants

- Reducing vehicle idling time – by installing telematic systems in all of our lorries that enable us to monitor vehicle activity and ultimately reduce fuel consumption and vehicle emissions. We also encourage our drivers to use cruise control when it’s safe and appropriate to do so

- Paying closer attention to our routes – this helps make sure our drivers follow the most fuel-efficient routes. We’re also constantly monitoring live traffic alerts to avoid delays and reduce the amount of time they’re out on the road

- Fitting air deflectors in all of our lorries – that are designed to guide airflow over the vehicles, helping reduce emissions and fuel consumption in the process

- Inspecting our fleet on a regular basis – we carry out tyre inspections every month, which involves checking for any wear and tear and making sure the air pressure hasn’t dropped, which can reduce fuel consumption by 3%. We also carry out all-over vehicle checks and maintenance every six weeks to make sure our fleet remains in an excellent condition

- Regularly investing in new lorries – we’re continuing to update our fleet with more fuel-efficient models. Our latest investment was at the start of the year, when we took delivery of a DAF LF 260, which is Euro 6 compliant. We’re currently awaiting delivery of two DAF CF vehicles, which are due on-site in two months’ time

We’re extremely proud of what we’ve achieved so far, but know there’s still more we can, and are doing, to continue our commitment to reducing our carbon footprint company-wide.

At the same time, we’re also helping our customers take significant sustainability-focused strides forward too. For more details, take a look at this blog, ‘How we helped Origin Global 100% improve their scrap recycling rates.’