Q&A: Is it worth recycling aluminium?

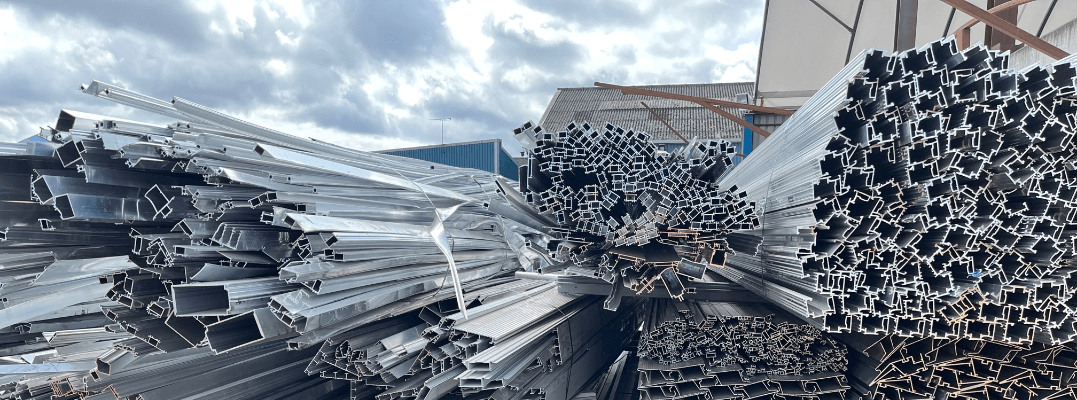

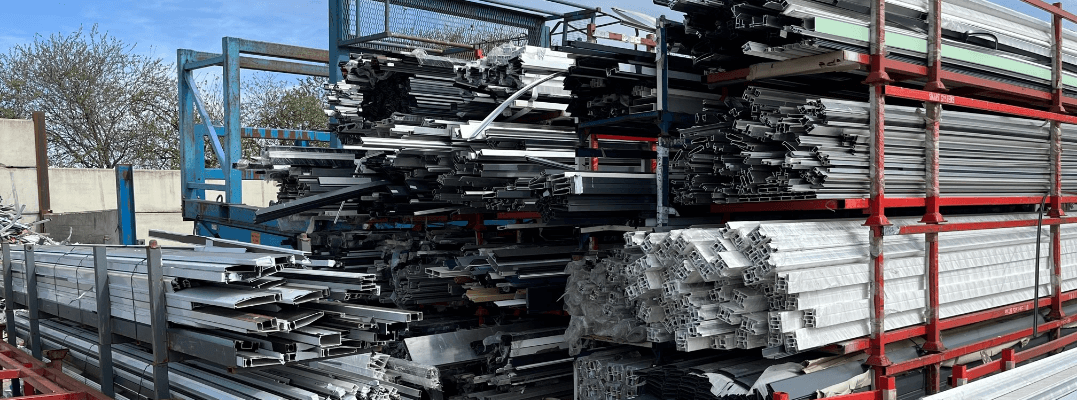

Every year, we recycle more than 30,000 tonnes of aluminium, giving new life to extrusion, sheet offcuts, non-ferrous materials and UTC cans. We know the true value of metal recycling, but unless you see the actual benefits, it’s easy to question if it’s worth recycling aluminium at all.

In this special Q&A blog, we get our commercial manager’s, Ed George’s, views on the importance of aluminium recycling. He also reveals some interesting qualities about aluminium and dispels some common myths.

Q. Is it worth recycling aluminium?

A. In a nutshell, yes it is, and I’m not just saying this because it’s what we do. There are several notable environmental benefits to recycling aluminium, which include saving energy and natural resources, as well as reducing the amount of scrap that’s sent to landfill.

To put this into further perspective, the actual process of recycling aluminium uses significantly less energy – a whopping 95% less – compared to the energy that’s required to actually create it. What’s more, every single element of aluminium is recyclable, which means greater carbon savings can be achieved every time it’s recycled. The sustainability credentials associated with aluminium recycling are vast; these two facts are merely just the tip of the iceberg.

From an organisational perspective, aluminium recycling enables fabricators, metal merchants, councils and waste management companies to generate additional income and boost their green credentials at the same time. More specifically, aluminium recycling is beneficial for businesses because:

- Using recycled billet instead of primary billet – involves 95% less energy than mining from the ground, which is a major carbon footprint enhancer in itself

- Aluminium is lightweight yet extremely durable – so lends itself well to endless applications

- Unlike other metals, aluminium doesn’t corrode over time – it can remain in-situ for decades

Q. What happens to aluminium waste?

A. In terms of how we handle aluminium waste, once it’s been delivered or we’ve collected it and brought it back to our site in Oldbury, we start analysing it. This involves grading it by alloy specification – there’s an abundance of differing alloy specifications, which aren’t all compatible with one another when it comes to remelting.

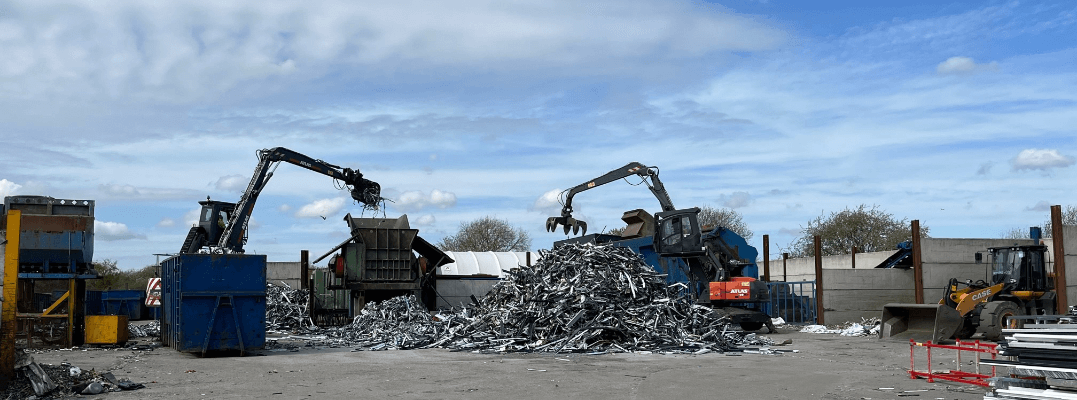

Any longer, leftover pieces of aluminium are shredded. These shreds of metal are then put through eddy currents and x-ray scanners to identify and extract any contaminants, such as packaging waste and plastic attachments.

In the case of aluminium cans, which we treat differently to other aluminium, we shred and remove any general waste from them. The shreds are the bailed into cubes of aluminium that are 97% clean – which is the optimum condition for the remelts we send it to because it’s melt-ready.

Q. Is aluminium waste hazardous?

A. No, aluminium definitely isn’t a hazardous material. On the contrary, it’s an extremely clean and green material due to its recyclability credentials and endless applications.

Incidentally, we are a non-hazardous site, so if any form of hazardous material was to somehow find its way on to our premises, our x-ray detection system would identify it. The system’s fitted on our main entrance and if it were to be activated, any vehicles that have just driven through our gates, would be asked to immediately turn around so we could inspect their load for hazardous materials.

Q. Can aluminium be 100% recycled?

A. Yes, as mentioned at the start of this article, one of the most notable and appealing credentials about aluminium is that every single element of it can be recycled.

What makes this fact and aluminium even more fascinating, is that it can be recycled an infinite number of times and still retain exactly the same chemical properties. More than 8% of the earth’s crust is made from aluminium which, coupled with the recyclability of the material, essentially means we will never run out of it. More than 75% of the aluminium that’s produced is still in use today in all sorts of forms, from windows, doors and automotive parts, to aerospace components, cans and stairlifts.

Q. Can aluminium cans biodegrade?

A. No, aluminium cans aren’t biodegradable. Interestingly, while aluminium cans can take just a matter of weeks to manufacture, it can actually take more than 200 years for them to start to decompose, and even then, they won’t fully break down.

Interestingly, after plastic bags and bottles, which can take up to 1,000 years to decompose, aluminium cans are widely recognised as taking the longest to biodegrade.

Aluminium is a material that is worth recycling for so many reasons. In fact, it’s very make-up naturally lends itself to being recycled time-and-again.

We hope you’ve found this Q&A useful, if you have any queries or would like to discuss your aluminium requirements with us, email Ed at ed.george@alutrade.co.uk

In the meantime, for a real-life look at how aluminium recycling can radically improve carbon footprints, read, ‘How we helped Origin Global 100% improve their scrap recycling rates.’