What are the most common aluminium products to be recycled?

Aluminium recycling is big business. Globally, more than 30 million tonnes of aluminium is recycled every year. On a UK level, over 160,000 tonnes of aluminium packaging alone is recycled annually.

From our perspective, we recycle in the region of 25,000 tonnes of aluminium at our site in Oldbury every single year. Over the last five years, we’ve recycled 115,000 tonnes of the stuff.

Every day, mountains-upon-mountains of products made from aluminium are recycled by organisations across the world, including us. And while these aluminium recycling streams may be handled using largely similar processes fundamentally, the size and type of aluminium products being recycled varies, especially from sector-to-sector (more on this a bit later on). And, of course, they vary according to residential and commercial use too.

Common residential aluminium products that are recycled

The average wheelie bin contains all sorts of aluminium bits and pieces of rubbish, which almost-always includes:

- Foil

- Drinks cans – we’ve worked hard over the years to clean up Used Beverage Can (UBC) recycling. Discover how we’ve gone about it

- Food containers

- Disposable trays

- Drinks bottles – aluminium bottles are becoming increasingly used by companies, such as Coca-Cola, instead of plastic bottles in their quest to become more sustainable

- Paint cans

- Aerosol cans

Common commercial aluminium products that are recycled

Commercially, the volume of aluminium products that are in circulation and go on to be recycled is extensive; far too extensive to cover off in this post. However, we still wanted to provide you with a flavour of the most common commercial aluminium products that are recycled – from our perspective.

We’ve been recycling aluminium since the late 1980s, and while we may have observed all sorts of industry-wide changes and considerably reviewed and refined our processes along the way, we’re largely recycling the same core products:

- UBC

Our UBC recycling expertise is not only proven, but pioneering. In 2010 alone, we recycled a third of all cans that were produced in the UK that year. In a typical year, we produce in the region of 390,000 UBC recycling bales, which equates to around 9,000 tonnes of aluminium.

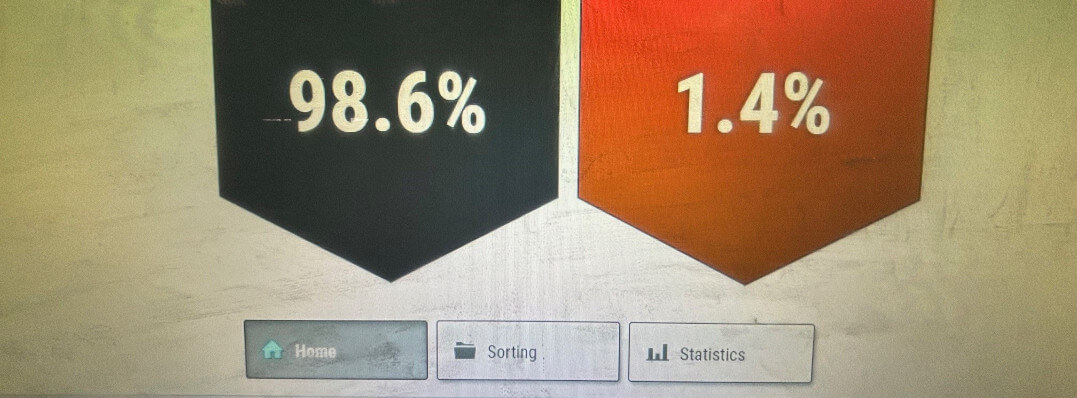

Volume of UBC recycled so far this year: 5,600 tonnes

- Extrusion scrap

We handle around 11,000 tonnes of extrusion scrap every year, which includes All Mill finish (clean) alloys, painted aluminium and Thermal Break. We recycle extrusion from all sources and in all forms, including offcuts from aluminium fabricators and door and window frames from installers and construction companies.

Volume of extrusion scrap recycled so far this year: 7,200 tonnes

- Portable aluminium roadways

Thanks to our continuous equipment investment, we have the necessary kit in place to be able to efficiently and effectively recycle these tracks, which is a massive feat. Our recently-installed Bano shredder is so mighty, it’s capable of chewing up and spitting out two track way boards at a time.

Volume of railway tracks recycled so far this year: 500 tonnes

Common aluminium products that are recycled – in other sectors

Aluminium products exist industry-wide, with growing numbers of organisations tapping in to the power of aluminium recycling to reduce their carbon footprint. Over the years, especially in recent years, aluminium has been increasingly recognised as a more environmentally-friendly, futureproofed alternative to other materials, such as plastic (e.g. Coca-Cola’s bottle packaging shift we referenced earlier) and bricks and cement.

Let’s take a closer look at three sectors in particular that are powering ahead when it comes to incorporating aluminium recycling into their current and future processes.

Automotive

One of the pioneering sectors when it comes to leading the charge for embracing a net zero future, the automotive industry continues to generate multiple headlines for its sustainable vision, which electric vehicles play a key part in. Electric vehicles aside, it’s widely reported that the sector is set to be revolutionised from every angle, including materials innovation.

Recycling aluminium is recognised as being a pivotal gear change towards decarbonising automotive manufacturing processes and achieving full loop circularity. Meanwhile, other benefits of automotive manufacturing include: lightweight profile (ideal for Battery Electric Vehicles), smaller components, increased safety and enhanced durability.

Typical automotive aluminium products that are recycled include: panels, doors, visors, radiators, rims, hubs, gearbox housings and engine mounts.

Construction

The construction sector is rapidly moving in the same direction as the automotive sector in relation to embracing the widespread benefits of a) using low carbon aluminium and b) recycling it, overshadowing more traditional and not so environmentally-friendly products, such as concrete and steel, due to their higher embodied carbon levels. Not only does it have a long lifespan when used for construction purposes, aluminium is extremely durable in all weather conditions and requires minimal to zero maintenance.

As for aluminium construction innovation, it’s everywhere, with new developments being unveiled by the day, including using twisted mesh, broken bike frames and used car parts to create aluminium building components.

Typical construction aluminium products that are recycled include: skirting, roofs, cladding, window and door frames, solar panels, staircases, hand rails and air con systems.

Packaging

The packaging world is a hotbed of activity when it comes to using aluminium to transform the future of packaging as we currently know it. Metal packaging overall reportedly holds an 11% share of the overall packaging market and a 30 to 40% share within the beverage packaging category.

Aluminium’s ability to preserve the quality and, in some cases, extend the shelf life of certain products has led to it being increasingly recognised as a future packaging solution for many brands, including Diageo whose Bailey’s Original Irish Cream Liqueur is no longer manufactured in glass, but lightweight aluminium bottles.

Typical packaging aluminium products that are recycled include: drinks cans and bottles, food cans and tins, foil and deodorant cans (by switching to aluminium cans for its Nivea Men deodorant, Nivea has cut its C02 emissions by at least 28%).

The use of aluminium to help companies to innovate and boost their green credentials has exceptional two-fold potential: in phasing out less planet-friendly processes and materials and in making sure products can be reused over and over again. And the best thing is, the best is yet to come in relation to aluminium-fuelled innovation and results.