Investing in our future & commitment to being an aluminium recycling leader

Our investment programme is central to our success – installing the latest equipment and continuously updating our fleet enables us to continue to deliver industry-leading results.

By this, we mean recovering 99% clean aluminium, handling in the region of 8,400 tonnes of UBC every year and successfully closing the aluminium loop once and for all.

But, of course, we couldn’t achieve these outputs without the state-of-the-art machinery we’ve got set up behind the scenes, as well as the high spec vehicles our teams drive around in. With that in mind, here’s a snapshot of some of the areas we’ve recently invested in:

Our fleet

Our trucks rack up some serious miles every year, which is why we regularly upgrade them to make sure they’re fit for purpose and are Euro 6 compliant. We currently make more than 6,000 annual collections, with our fleet of 12 lorries clocking up in the region of 41,000 miles, per vehicle, every year.

At the time of writing this post, we’d just purchased two UK DAF trucks, taking our current fleet to 12.

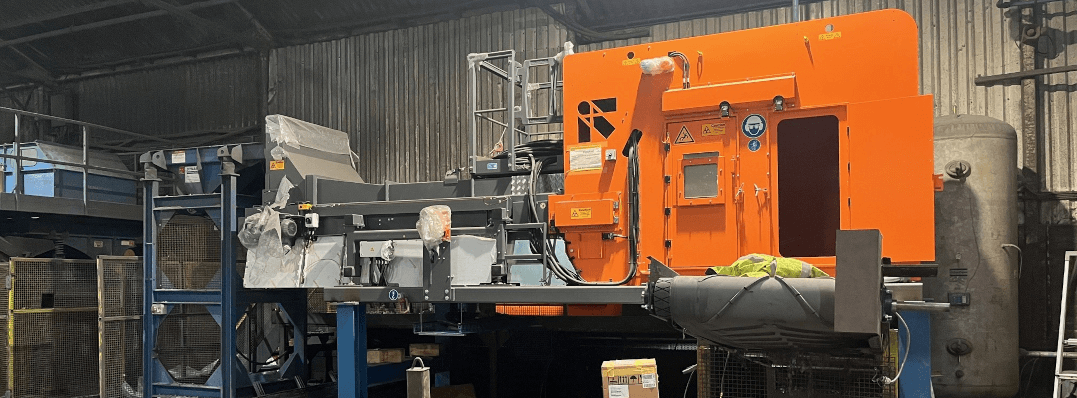

Our shredder

Our shredder sits at the heart of our operations, crunching up and spitting out mountains of aluminium every single day. It’s a bit of kit that is majorly put through its paces, so it’s vital that it works at an optimum level 24/7.

Given the fact we’d had our old shredder for several years, we recently replaced it with a brand new model, which is our largest equipment investment to date. And the investment has immediately paid off, the new shredder is capable of chewing up not one, but two track way boards at a time:

Our grabs

Our grabs may not be as impressive as our shredder, but they play a fundamental role in helping the team pick, sort through and shift all of the aluminium we process.

We aim to update our grabs, as well as our diggers, around every five years. Like everything on our site, they work extremely hard and they work a lot of hours every single day, which means they naturally need replacing as the years go by.

Our x-ray machine

We were the first company in the world to install a new generation X-TRACT™ system, which has enabled us to increase our material processing outputs from one to two tonnes to between four and five tonnes an hour.

More recently, we doubled down on our success by installing a second, new generation X-TRACT™ unit. (For the full details, read ‘Doubling down on our precision-focused approach to aluminium recycling.’)

Investing in our equipment and fleet is second nature to us. We are constantly reviewing and refining our processes so that we can continue to provide our UK-wide customers with aluminium recycling services that are highly efficient, effective and always ahead of the curve.