Stepping up our aluminium recycling productivity with our new shear machine

We’re constantly updating our equipment so that we can continue to provide our customers with industry-leading aluminium recycling services.

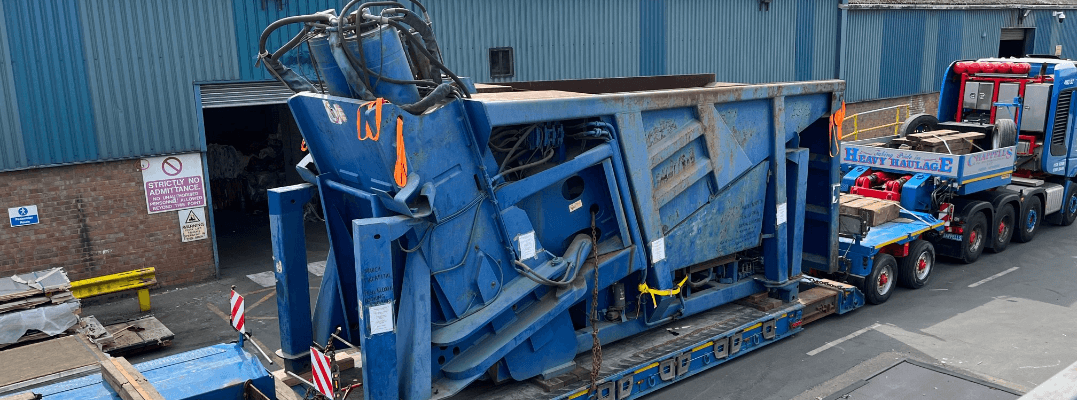

Among our latest investments is our Bonfigioli Squalo 2000 shear machine. This new piece of kit has replaced our Danieli Henschel 250 Grinder Mill, which we’d had for ten years.

Imported from Mexico, the Bonfigioli is an invaluable £250,000 investment. It crops down materials from six to seven metres in length to around 1.5 metres in 20 seconds, forming a key step within our pre-process long length extrusion handling. Once it’s been through the Bonfigioli, the long length extrusion is ready for the next stage in the aluminium waste recycling process – shredding.

Ed George, our Commercial Manager, says the Bonfigioli represents more than just an equipment investment because it’s enabling us to improve our operational outputs.

“Investing in this particular machine means we’ve increased our productivity levels and capacity,” he explains.

“The extrusion used to have to make three passes through our grinder mill to get it into a shredder-ready state. Now, in comparison, it only has to go through the Bonfigioli once.

“This means we can maximise our throughput by 60%. At the same time, we can also keep our skips freed up so that we can maintain our 48-hour window for collections.”

The Bonfigioli is our second machine. It’s been set up next to our first Drake 16 hammer mill shredder machine in our outside yard and has been adapted so that it’s just right for us.

“When the machine arrived, it was equipped with a diesel engine. We’ve stripped this out and installed an electric engine. As a result, there’s less noise and no fumes,” adds Ed.

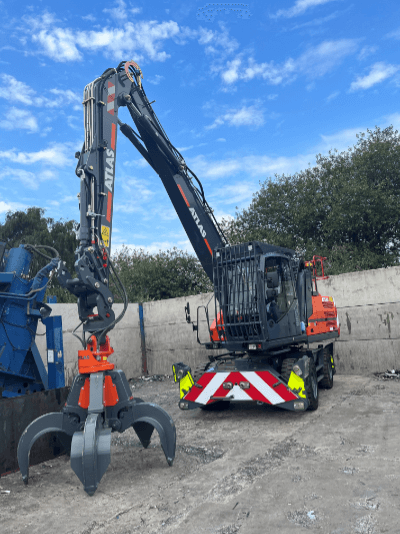

The Bonfig investment comes in addition to a trio of vehicle and wider equipment investments. We’ve recently taken delivery of two DAF CF lorries, costing £135,000 each, and a £220,000 Atlas 200MH grab lorry.

Ed concludes: “Investing in the very latest equipment and up-to-date fleet helps make sure we are futureproofing our business. Being able to provide highly effective and efficient aluminium waste recycling services is why our customers choose us time and again.

“It also illustrates the fact we’re a business that’s fully committed to moving with the times and embracing the very latest advances.”

For more information about our services or to discuss your aluminium recycling requirements with us, email Ed at ed.george@alutrade.co.uk